The tubular resistance furnace is used for chemical analysis, physical identification and heating in laboratories, industrial and mining enterprises and scientific research institutions.Tubular resistance furnaces, with high quality and excellent performance, are well received by thousands of new customers every year. The harmony of functionality and design, coupled with the excellent price-performance ratio, makes this collection their ultimate choice.

Learn more

Trolley-Type Resistance Furnace

All-fiber trolley resistance furnace is a cycle furnace, a large industrial furnace, mainly for the general large, medium-sized castings or alloy parts at rated temperature for heat treatment purposes.

Learn more

High-temperature lifting furnace (SPK-RD1400)

SPK series lifting furnace is a new type of electric furnace independently developed and produced by SPK company. It introduces advanced technology, has advanced and reasonable structure, beautiful and generous appearance. The shell is made of cold-rolled steel plate, processed by advanced CNC machine tool, luxurious and beautiful two-color epoxy powder electrostatic spray molding process, and is resistant to high temperature and corrosion. It uses excellent heating elements. The double-layer furnace shell is equipped with an air cooling system, which can quickly cool down; The furnace has the advantages of balanced temperature field, low surface temperature of furnace body, fast temperature rise and fall rate, and energy saving.

Learn more

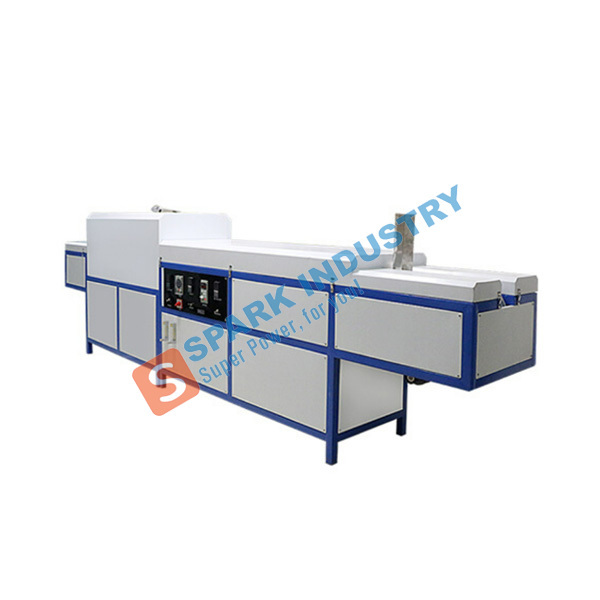

High temperature mesh belt furnace

The mesh belt furnace is suitable for heating aluminum bars, copper bars, red stamping, annealing of castings, glass and products, tempering of small parts and other heat treatment.

Learn more

SPK₁-Silicon Nitride Ceramic Igniter

It is used for various boilers and gas silicon nitride igniters. It has the characteristics of high power. Therefore, it is mainly used for medium-sized combustion equipment, commercial stoves, biological boilers, heating stoves, circulating thermal baking ignition heating boxes, etc.

Learn more

SPK₂ - Silicon Carbide Ceramic Igniter

Silicon carbide ceramic igniter is used for various boilers and gas silicon nitride igniters. It has the characteristics of high power. Therefore, it is mainly used for

Learn more

SPK₃ - Silicon Nitride Ceramic Glow Plug, Igniter

Silicon nitride ceramic glow plugs, heating elements, igniters, silicon nitride ceramic glow plugs "Car ceramic glow plugs" are used for diesel engines and gasoline engines to start preheating, and to ignite various high-temperature gases.

Learn more

Copper and stainless steel heating tubes

A copper electric heating tube is a metal tube into which an electric heating element is placed.

Learn more

The double U-shaped heating tube is made of a metal tube as the outer shell (including stainless steel and copper tubes), and spiral electric thermal alloy wires (nickel chromium, iron chromium alloy) are uniformly distributed along the central axis of the tube. The gaps are filled and compacted with magnesium oxide sand with good insulation and thermal conductivity. The ends of the tube are sealed with silicone gel. This metal armored heating element can heat air, metal molds, and various liquids.

Learn more

The spiral heating tube is a tubular electric heating element with a structure in which an electric heating wire is placed inside a metal tube and the gaps are tightly filled with crystalline magnesium oxide with good thermal conductivity and insulation. The two ends of the electric heating wire are connected to the power supply through two lead out rods. It has the advantages of simple structure, long service life, high thermal efficiency, good mechanical strength, and can be bent into various shapes for safe use. Using high-quality materials and strict process technology, we produce electric heating tubes with excellent electrical insulation performance and extremely high electrical strength.

Learn more

Tubular electric heating element

Tubular electric heating element (abbreviated as electric heating tube) is an electrical component that specifically converts electrical energy into thermal energy. It is made of metal tubes as the outer shell (including stainless steel and copper tubes), and spiral electric thermal alloy wires (nickel chromium, iron chromium alloy) are uniformly distributed along the central axis of the tube. The gaps are filled and compacted with magnesium oxide sand with good insulation and thermal conductivity. The ends of the tube mouth are sealed with silicone gel. This metal armored electric heating element can heat air, metal molds, and various liquids.

Learn more

It adopts U-shaped tubular electric heating elements, which are assembled on the flange cover according to the design specifications of different heating media and power configuration requirements. It is inserted into the material to be heated, and the large amount of heat emitted by the heating element during operation is transmitted to the heated medium, causing the temperature of the medium to rise and meet the required process requirements. When the medium temperature reaches the set value required by the process, the control system will adjust the output power of the electric heater based on the temperature sensor signal and PID calculation to achieve temperature control of the resistive load of the heating element. Make the medium temperature uniform and meet the required requirements; When the heating element exceeds the temperature or low liquid level, the interlocking protection device of the heating element immediately cuts off the heating power to prevent the heating element from burning out and prolong its service life.

Learn more