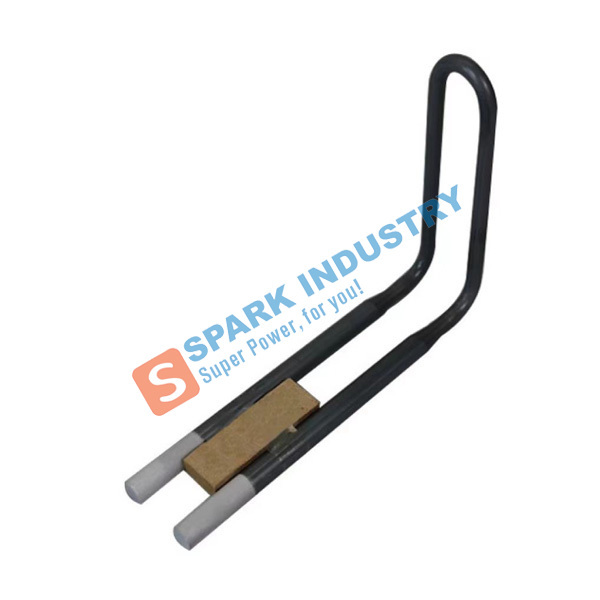

MoSi₂ Element Special Fixture Conductive Connection Belt

Keywords:

MoSi₂ Element Special Fixture Conductive Connection Belt

Mosi2 Heaters For Dental Furnace

- Description

-

MoSi2 Element Special Fixture Conductive Connection Belt

The connecting wires that come into contact with MoSi2 components are made of aluminum braided tape or multi-layer aluminum foil. The clamp on the outside can only serve as a clamp and does not need to conduct electricity. The end of the wire is connected to the busbar. To prevent stress from being transmitted to the component, the length of the wire should be slightly greater than the straight distance between the component and the busbar.

Fixing clip Elementholder

The weight of the entire MoSi2 component is borne by the fixed clamp, and the position of the component is also determined by it. Therefore, careful installation is necessary to ensure that the components are vertically suspended. To avoid local overheating, the conical part of the lower end of the components must extend into the furnace.

When installing MoSi2 components, do not tighten the screws on the clamp too tightly at once. When the components reach high temperature, tighten them again because the components have a certain degree of plasticity and are not easy to break. The temperature of the clamp part should generally not exceed 200 ℃, therefore, the contact voltage between the clamp wire and the component should be reduced by 0.1V. To avoid radiative heat transfer to the chuck, the distance between the lower end of the chuck and the top of the brick should be less than 50mm. In order to avoid damage, generally 6/12mm diameter components cannot be used for a long time with 170A, and 9/18mm diameter components cannot be used for a long time with 300A.

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!