Electric heater element single U-shaped heating tube

The characteristic of U-shaped electric heating tubes is to place electric heating wires inside seamless metal tubes (carbon steel pipes, titanium pipes, stainless steel pipes, copper pipes), and tightly fill the gaps with crystalline magnesium oxide with good thermal conductivity and insulation. The two ends of the electric heating wires are connected to the power supply through two lead out rods, and the gaps are filled with magnesium oxide powder with good thermal conductivity and insulation before shrinking the tubes, Because the electric heating tube is curved like the English letter U, it is called a U-shaped electric heating tube. Its specifications can be customized according to user needs, and it has the characteristic of simple structure.

Learn more

Finned electric heating tubes are made by wrapping metal heat sinks on the surface of ordinary components, which expands the heat dissipation area by 2-3 times compared to ordinary components. That is, the surface power load allowed by finned components is 3-4 times that of ordinary components. Due to the shortened length of the components, their thermal losses are reduced. Under the same power conditions, they have advantages such as fast heating, uniform heating, good heat dissipation performance, high thermal efficiency, long service life, small heating device volume, and low cost. Designed reasonably according to user requirements for easy installation. The product is widely used in industries such as mechanical manufacturing, automobiles, textiles, food, and household appliances, especially in the air conditioning curtain industry.

Learn more

Molybdenum is a silver white metal with an atomic radius of 0.14nm, an atomic volume of 235.5px/mol, a coordination number of 8, and an Az type body centered cubic crystal system with a spatial group of O. No isomeric transformation has been found to date. The lattice parameters of molybdenum at room temperature range from 0.31467 to 0.31475nm and vary with impurity content. Molybdenum has a high melting point and ranks sixth among elemental substances in nature, known as a refractory metal. The density of molybdenum is 10.23g/cm ³, About half of tungsten (tungsten density 19.36g/cm) ³)。 The coefficient of thermal expansion of molybdenum is very low; Molybdenum has a higher thermal conductivity. Low molybdenum resistivity: 5.17 at 0 ℃ × 10 Ω· cm; 24.6 at 800 ℃ × 10

Learn more

Product diameter specifications: Φ 20-300mm, and can be specially processed and made according to your drawing requirements. Mainly used for piercing seamless steel pipes such as stainless steel, brazing steel, bearing steel, and high-temperature alloy steel, and for hot rolling piercing of seamless pipes of different materials in high-temperature and harsh environments.

Learn more

Molybdenum electrodes have high high-temperature strength, good high-temperature oxidation resistance, and long service life. Based on these advantages, they are usually used in daily glass, optical glass, insulation materials, glass fibers, rare earth industry, and other fields.

Learn more

Electric heating radiation tube

Main technologies and performance of electric heating radiation tubes:

Learn more

Ceramic sheets and boards are stock shapes available as solid plates, slabs, and substrates. The board or plate may consist of a ceramic fiberboard product, a dense sintered ceramic plate, or a precast cement bonded slab.

Learn more

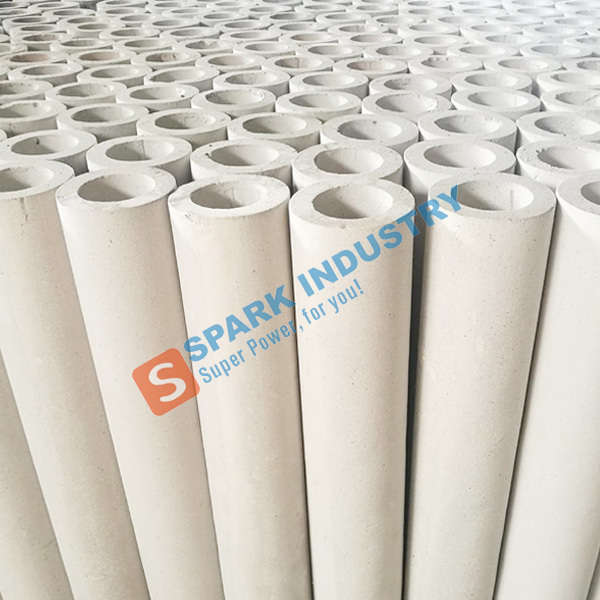

Ceramic tubes are ceramics used in certain devices, equipment, or structures that can withstand static or dynamic mechanical loads under high temperature conditions. It has a high melting point, high high-temperature strength, and small high-temperature creep performance, as well as good heat shock resistance, corrosion resistance, oxidation resistance, and structural stability. High temperature structural ceramics include two categories: high-temperature oxides and high-temperature non oxides (also known as refractory compounds).

Learn more

Customized Industrial Aluminum Ceramic Tube

Alumina ceramics have good conductivity, mechanical strength, and high temperature resistance. It should be noted that ultrasonic cleaning is required. Alumina ceramics are a widely used ceramic, and due to their superior performance, their applications in modern society have become increasingly widespread, meeting the needs of daily use and special performance.

Learn more

High Pressure Atomising Zirconia Nozzles

Zirconia ceramic nozzle have high wear resistance, which is twice as good as metal materials. Combined with polishing technology, their surface roughness reaches 0.03 μ m. Effectively reducing the resistance of liquid flowing through the in ner wall of the nozzle and improving injection efficiency.

Learn more

High Temperature White 99.7% Alumina Ceramic Tube

High purity aluminum oxide powder is a white micro powder with uniform particle size, easy to disperse, stable chemical properties, moderate high-temperature shrinkage performance, and good sintering performance; High conversion rate and low sodium content. This product is the basic raw material for producing heat-resistant, wear-resistant, and corroData Sheet

Learn more