U Type Silicon Carbide Rod

Keywords:

U Type Silicon Carbide Rod

- Description

-

U-shaped silicon heating element is manufactured by taking two carefully-matched SiC rods and welding a thickened silicon carbide bridge. This element provides for wiring both tail ends from one side of the furnace. The tail ends of the cold ends are metallized with aluminum, which can provide a low-resistance contact surface to the aluminum connection straps and clamps.

Since U-shaped silicon heating element is composed of two ED silicon heating elements sharing a cold end, it can be connected by the power cord at one end of the furnace. The surface temperature of heating part is 1500. It is mainly used in kilns with high furnace temperature and high temperature uniformity. Its characteristics are electricity saving and long service life.

In addition, a furnace with an energy saving structure can be built because the number of heating element holes on the furnace can be reduced compared with the U types. These elements are widely used as high-temperature heat sources for electric furnaces and for the firing of ceramic capacitors, ferrites and other electronic components.

Type: U-Shaped;

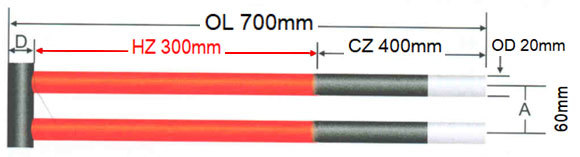

Outer diameter (OD): mm, Overall length (OL): mm, Hot zone length (HZ): mm, Cold end length (CZ): mm, Shank spacing (A): mm

Example: U Type, OD=20mm, HZ=300mm, CZ=400mm, OL=700mm, A=60mm, Resistance2.24Ω

Specify as: U Shaped,20/300/700/60/2.24Ω

Features :

1. High strength and excellent shock resistance;

2. Heat source is free of noise and air pollution;

3. Anti-oxidization;

4. Anti-corrosion,

5. Long service life,

6. Little deformation,

7. Easy installation and maintenance.

8. Excellent specific rate of heat zone resistance and cold end resistance,

9. Avoiding over-temperature of cold ends to damage the furnace body.

10. Saving energy

Outer Diameter

(OD, mm)Hot zone

(HZ, mm)Cold zone

(CZ, mm)Overall length

(OL, mm)Range of resistance

(ohms)8

100-300

60-200

240-700

2.1-8.6

14

100-500

150-350

400-1200

0.7-5.6

16

200-600

200-350

600-1300

0.7-4.4

18

200-800

200-400

600-1600

0.7-5.8

20

200-800

250-600

700-2000

0.6-6.0

25

200-1200

250-700

700-2600

0.4-5.0

30

300-2000

250-800

800-3600

0.4-4.0

35

400-2000

250-800

900-3600

0.5-3.6

40

500-2700

250-800

1000-4300

0.5-3.4

45

500-3000

250-750

1000-4500

0.3-3.0

50

600-2500

300-750

1200-4000

0.3-2.5

54

600-2500

300-750

1200-4000

0.3-3.0

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!