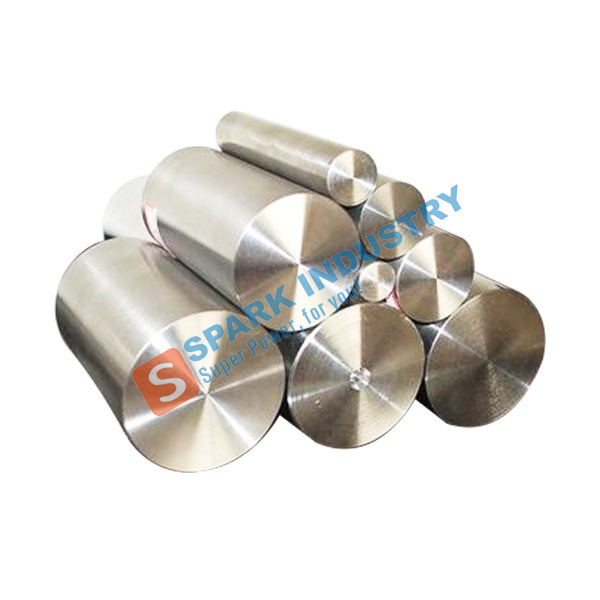

Anti Abrasion Inconel 718 Rod 3.0mm Nickel Chromium Alloys

Keywords:

Anti Abrasion Inconel 718 Rod 3.0mm Nickel Chromium Alloys

- Description

-

Anti Abrasion Inconel 718 Rod 3.0mm Nickel Chromium Alloys

Inconel 718 Rod Introduction

High temperature alloy has the high temperature hot corrosion and high temperature abrasion resistance,the metal material can work long-term which above 600 ℃ with under certain stress conditions.

Inconel 718 Rod Application:

High temperature components such as turbine blades, guide vanes, turbine disks, high pressure

compressor disks,machine manufacturing

and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines

Inconel 718 Rod Parameters

Item

Size

Plate/Sheet

0.5~60.0mm (THK)*2000mm(WIDTH)*6000mm(LENGTH)

Bar (Round)

Φ5.5~250mm

Bar (Square)

40~240mm*40~240mm

Strip

0.05~3.0mm (THK)*≤420mm(WIDTH)

Seamless Pipe

0.2mm~508mm (OD)*0.5mm~18mm(WT)

Welded Tube

0.5mm~120mm (OD)*0.05mm~10mm(WT)

Wire

Φ0.1mm~18mm

Chemical Composition of Inconel 718

ement

Content

Ni+Co

50 - 55 %

Cr

17 - 21 %

Fe

BAL

Nb+Ta

4.75 - 5.5 %

Mo

2.8 - 3.3 %

Ti

0.65 - 1.15 %

Al

0.2 - 0.8 %

Typical Properties of Inconel 718

operty

Metric

Imperial

Density

8.19 g/cm3

0.296 lb/in3

Melting point

1336 °C

2437 °F

Co-Efficient of Expansion

13.0 µm/m.°C

(20-100 °C)7.2x10-6 in/in.°F

(70-212 °F)Modulus of rigidity

77.2 kN/mm2

11197 ksi

Modulus of elasticity

204.9 kN/mm2

29719 ksi

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!